VX500 smart camera, make cobot-vision application easier

VX500 smart camera,

make cobot-vision application easier

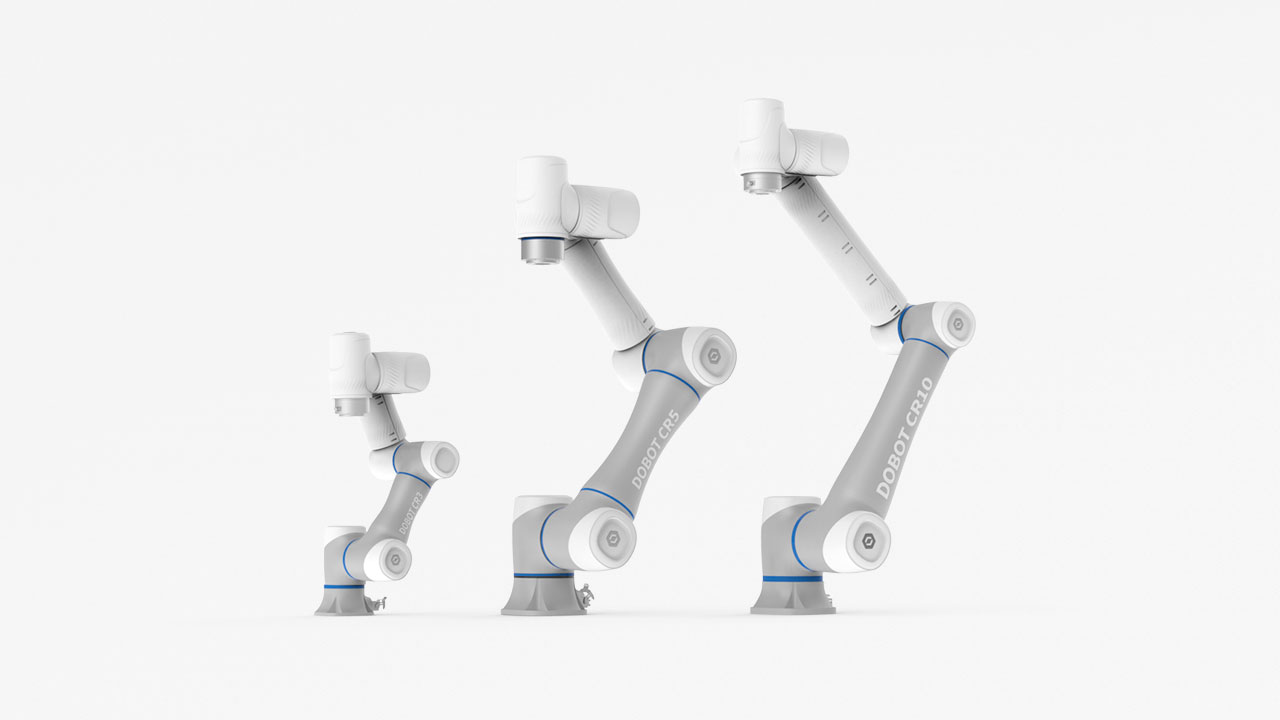

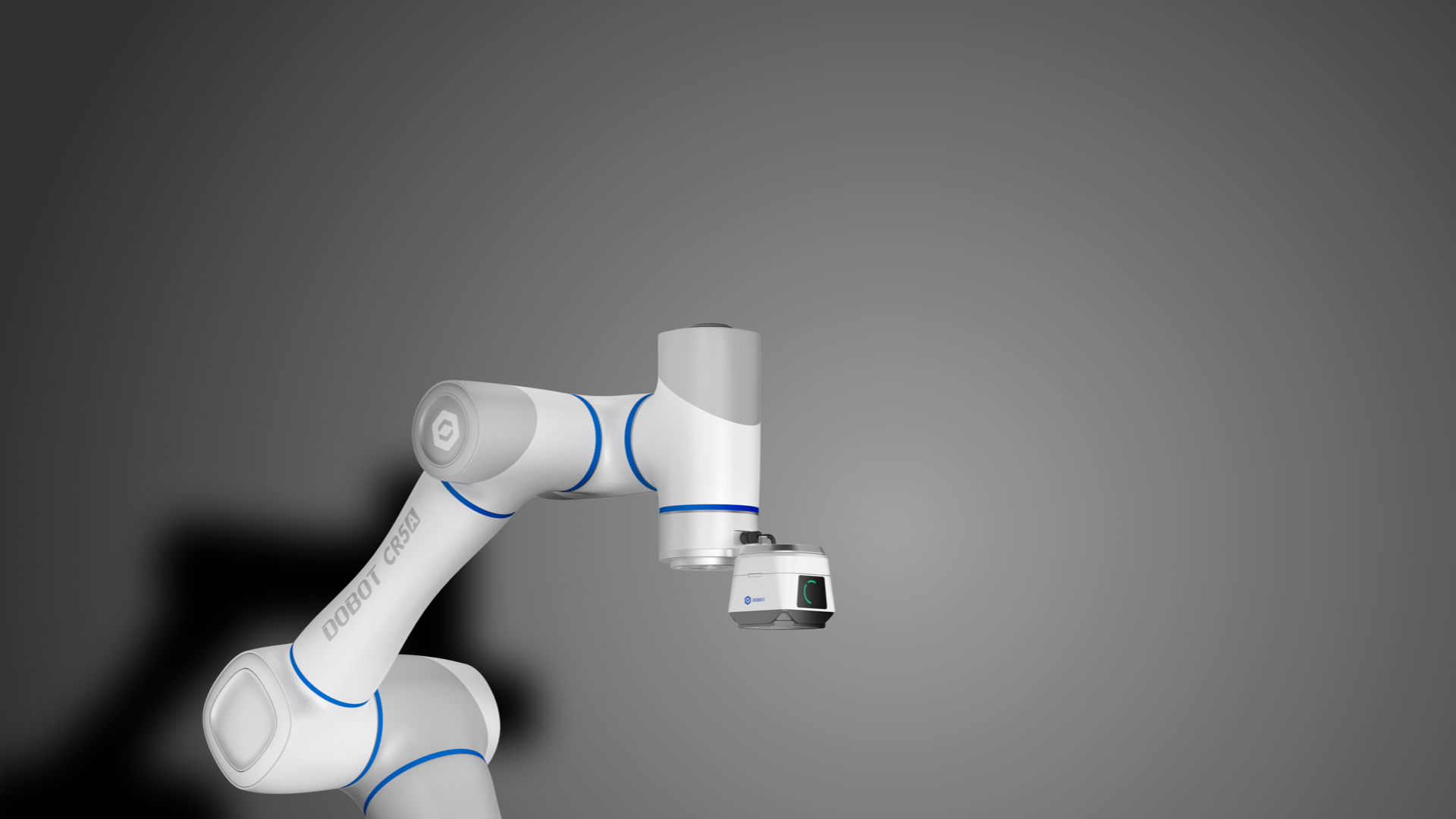

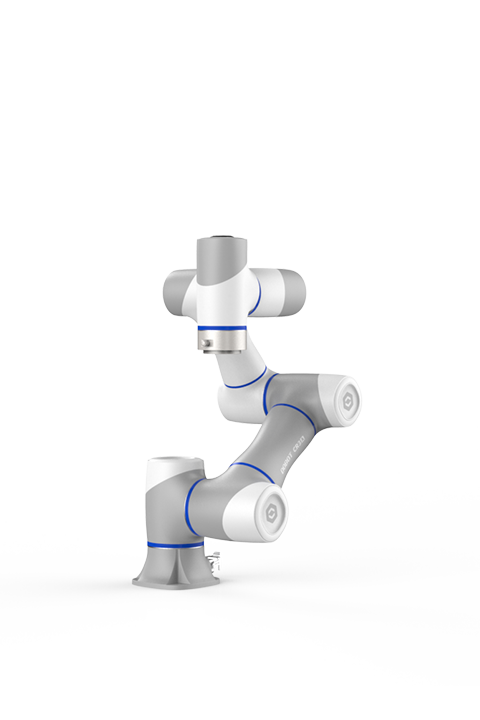

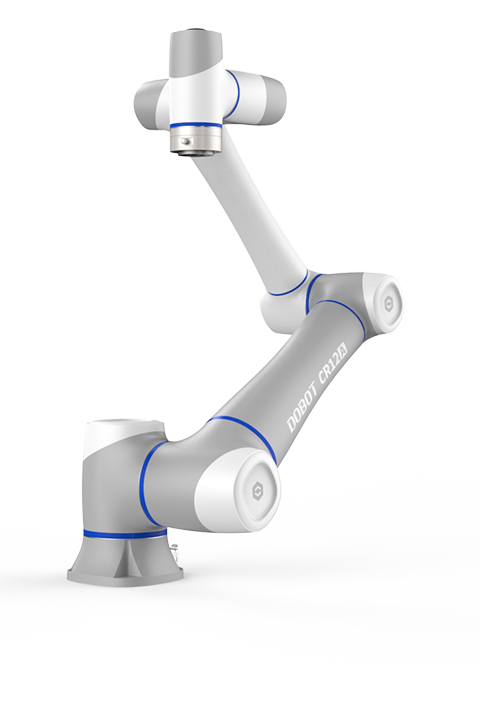

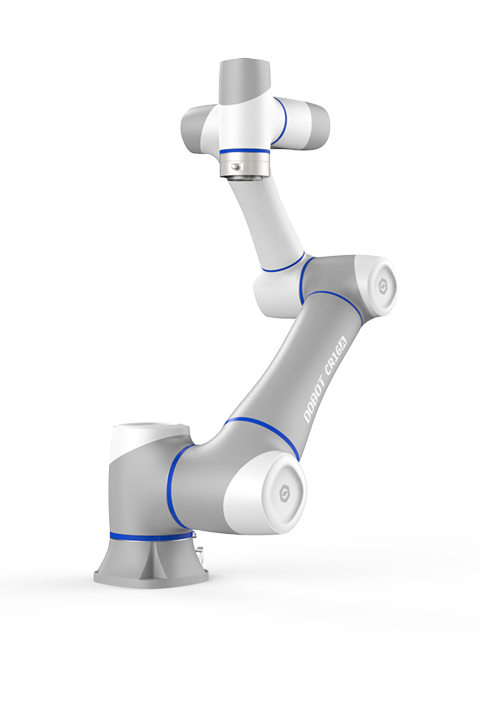

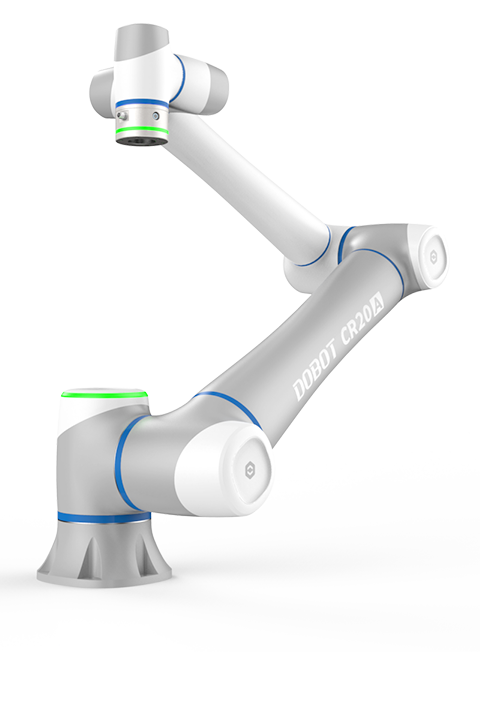

Our robots are equipped with a 5-megapixel camera, an LED light source, and high-performance 2.5D algorithms, allowing them to integrate vision and communication functions seamlessly.

They have exceptional precision in detecting changes in scene height and tilt, with an impressive spatial compensation accuracy of up to ±0.26mm.

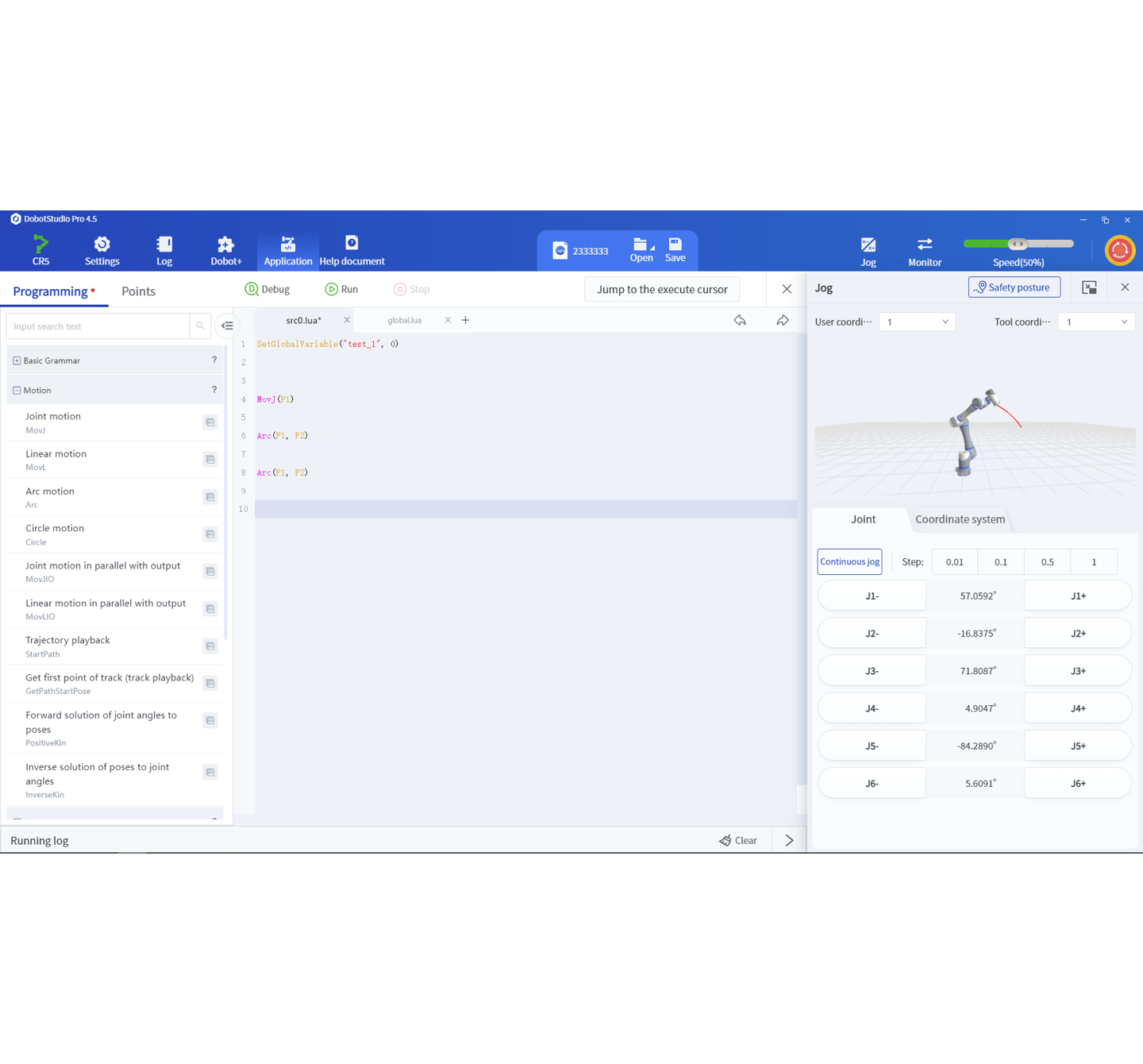

Moreover, their comprehensive error-proof detection algorithms enable the quick implementation of various vision applications, such as visual localization, measurement, inspection, and identification.

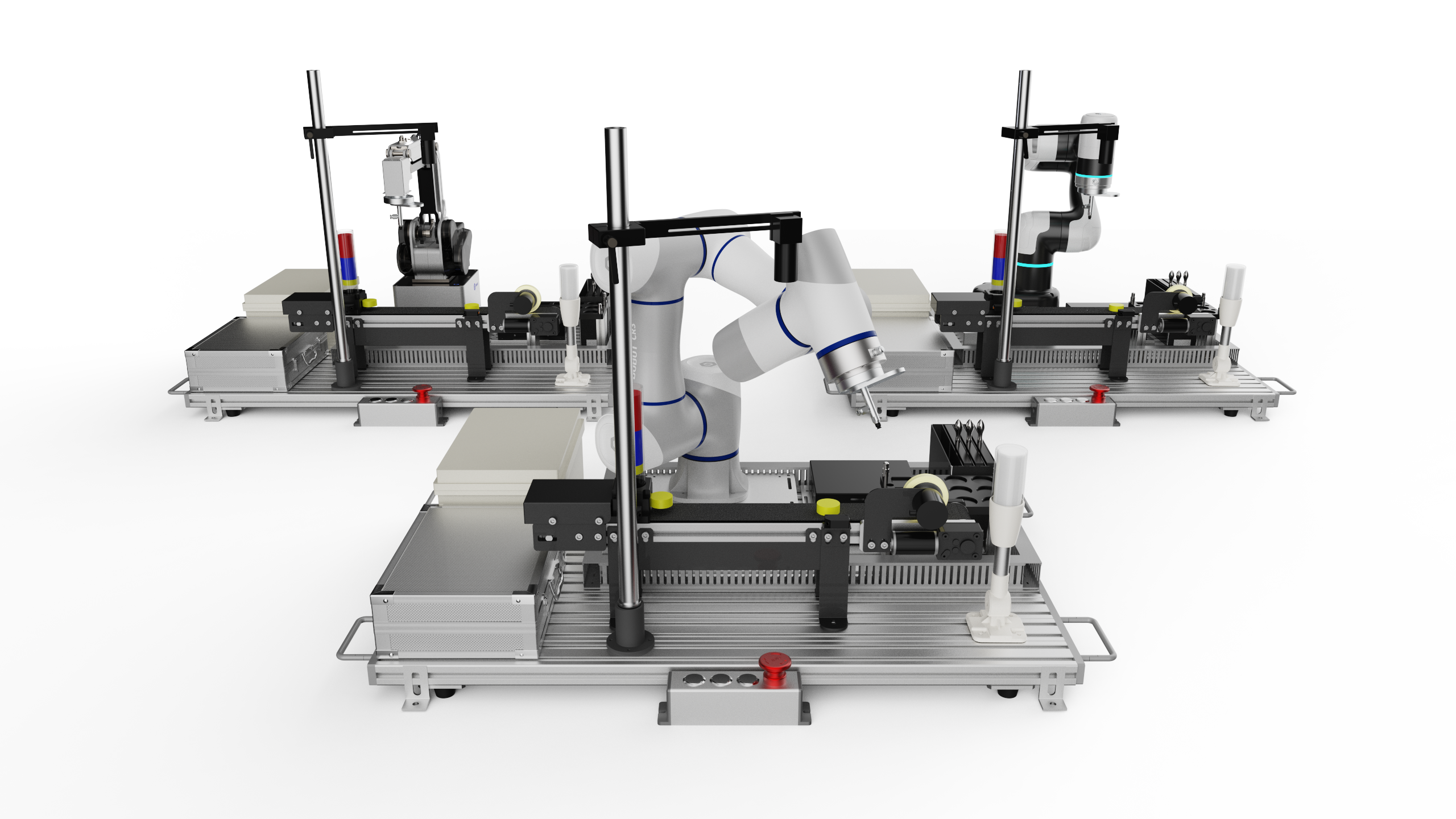

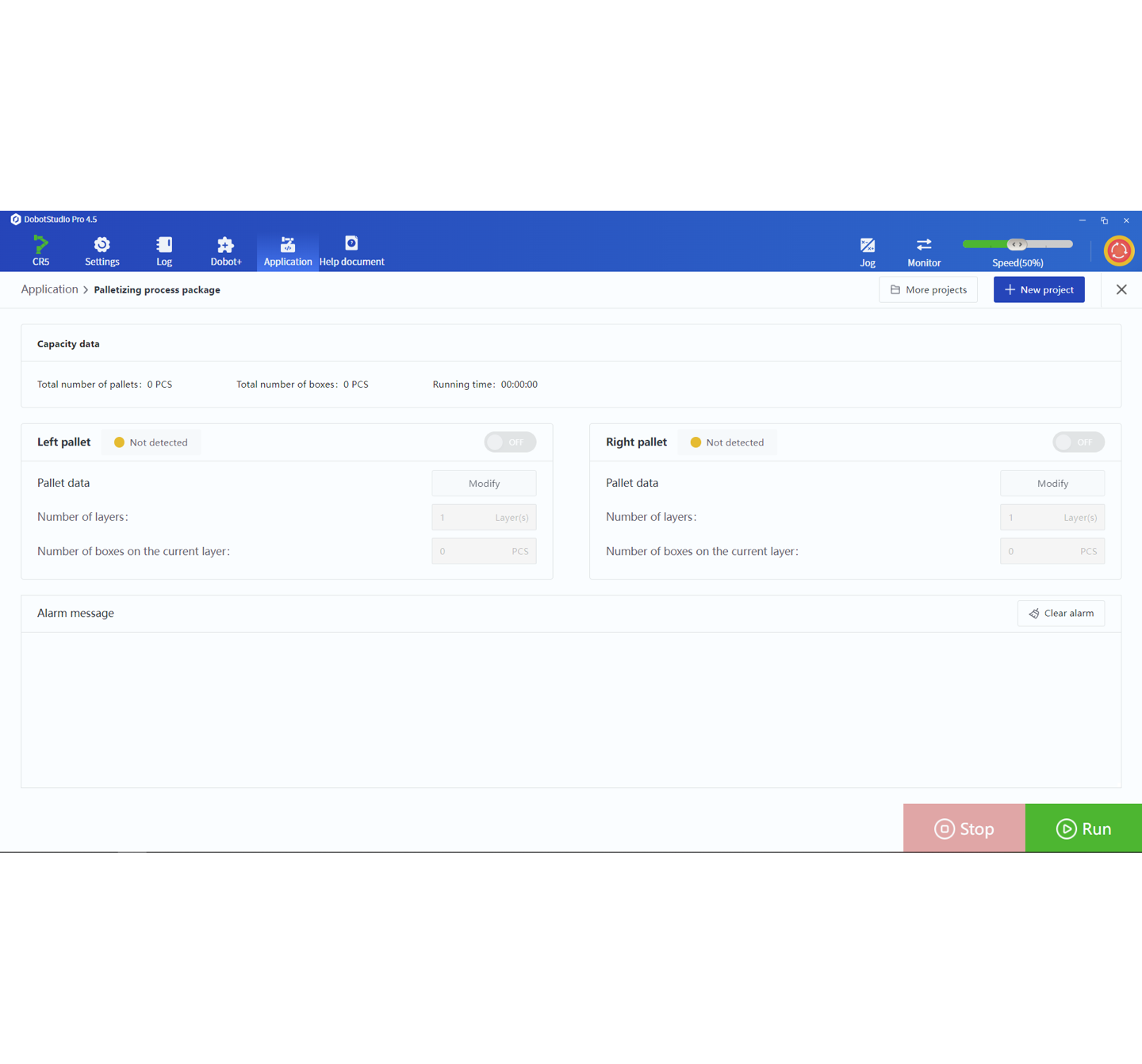

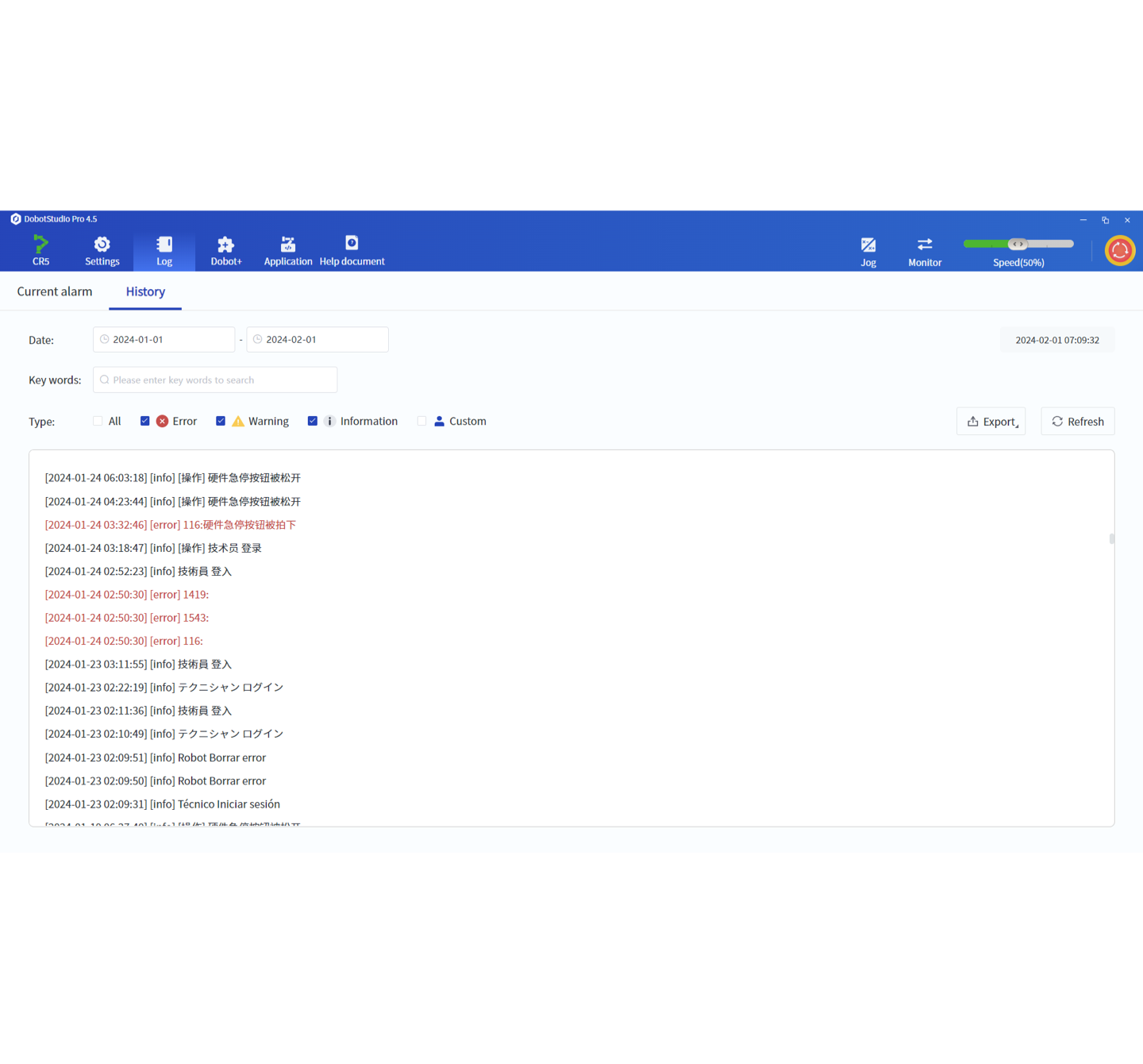

The smart camera can be easily integrated with DOBOT CRA, providing a plug-and-play functionality. This eliminates the need for selecting, assembling, external wiring, and hardware and software debugging, making the process of building vision solutions hassle-free.

* This is an optional accessory

Learn more

* This is an optional accessory

2.5D

high-performance localization algorithm

30 minutes

to start a vision application

5 megapixel

high resolution

±0.26 mm

spatial compensation accuracy