Auto Parts

Automotive

Consumer Electronics

Metal Processing

Food and Beverage

Lithium Battery

Solar

Home Appliance

Semiconductor

Chemical

Plastics

Agriculture

Healthcare

Logistics

Clothing and Textile

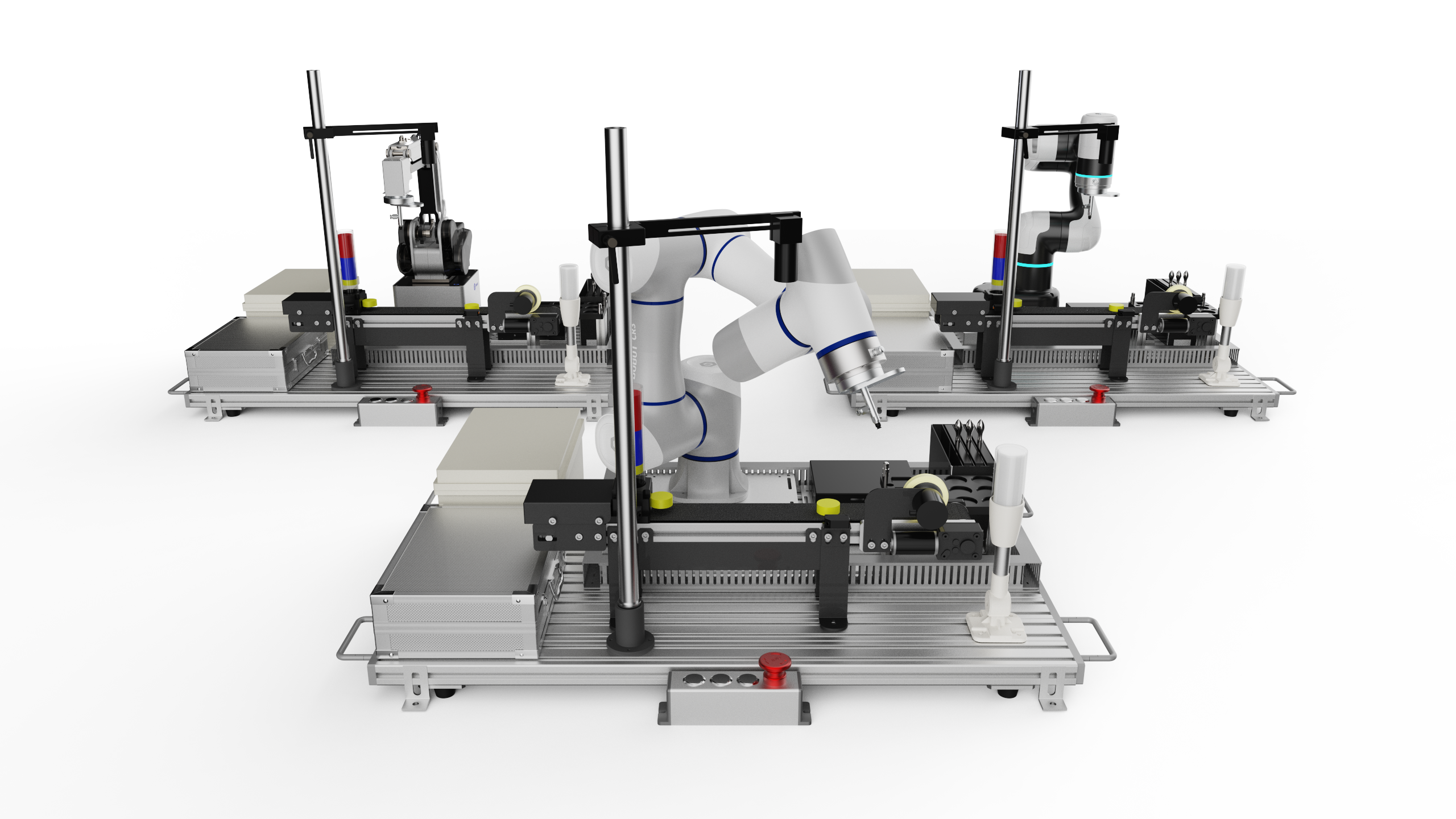

Education

Scientific Research

Other

Retail

Construction

Defense

Packaging

Mining

Cosmetics

Funiture

Energy

Andorra

United Arab Emirates

Afghanistan

Antigua & Barbuda

Anguilla

Albania

Armenia

Angola

Antarctica

Argentina

American Samoa

Austria

Australia

Aruba

Åland Islands

Azerbaijan

Bosnia & Herzegovina

Barbados

Bangladesh

Belgium

Burkina Faso

Bulgaria

Bahrain

Burundi

Benin

St. Barthélemy

Bermuda

Brunei

Bolivia

Caribbean Netherlands

Brazil

Bahamas

Bhutan

Bouvet Island

Botswana

Belarus

Belize

Canada

Cocos (Keeling) Islands

Congo - Kinshasa

Central African Republic

Congo - Brazzaville

Switzerland

Côte d’Ivoire

Cook Islands

Chile

Cameroon

China

Colombia

Costa Rica

Cuba

Cape Verde

Curaçao

Christmas Island

Cyprus

Czechia

Germany

Djibouti

Denmark

Dominica

Dominican Republic

Algeria

Ecuador

Estonia

Egypt

Western Sahara

Eritrea

Spain

Ethiopia

Finland

Fiji

Falkland Islands

Micronesia

Faroe Islands

France

Gabon

United Kingdom

Grenada

Georgia

French Guiana

Guernsey

Ghana

Gibraltar

Greenland

Gambia

Guinea

Guadeloupe

Equatorial Guinea

Greece

South Georgia & South Sandwich Islands

Guatemala

Guam

Guinea-Bissau

Guyana

Hong Kong SAR China

Heard & McDonald Islands

Honduras

Croatia

Haiti

Hungary

Indonesia

Ireland

Israel

Isle of Man

India

British Indian Ocean Territory

Iraq

Iran

Iceland

Italy

Jersey

Jamaica

Jordan

Japan

Kenya

Kyrgyzstan

Cambodia

Kiribati

Comoros

St. Kitts & Nevis

North Korea

South Korea

Kuwait

Cayman Islands

Kazakhstan

Laos

Lebanon

St. Lucia

Liechtenstein

Sri Lanka

Liberia

Lesotho

Lithuania

Luxembourg

Latvia

Libya

Morocco

Monaco

Moldova

Montenegro

St. Martin

Madagascar

Marshall Islands

North Macedonia

Mali

Myanmar (Burma)

Mongolia

Macao SAR China

Northern Mariana Islands

Martinique

Mauritania

Montserrat

Malta

Mauritius

Maldives

Malawi

Mexico

Malaysia

Mozambique

Namibia

New Caledonia

Niger

Norfolk Island

Nigeria

Nicaragua

Netherlands

Norway

Nepal

Nauru

Niue

New Zealand

Oman

Panama

Peru

French Polynesia

Papua New Guinea

Philippines

Pakistan

Poland

St. Pierre & Miquelon

Pitcairn Islands

Puerto Rico

Palestinian Territories

Portugal

Palau

Paraguay

Qatar

Réunion

Romania

Serbia

Russia

Rwanda

Saudi Arabia

Solomon Islands

Seychelles

Sudan

Sweden

Singapore

St. Helena

Slovenia

Svalbard & Jan Mayen

Slovakia

Sierra Leone

San Marino

Senegal

Somalia

Suriname

South Sudan

São Tomé & Príncipe

El Salvador

Sint Maarten

Syria

Eswatini

Turks & Caicos Islands

Chad

French Southern Territories

Togo

Thailand

Tajikistan

Tokelau

Timor-Leste

Turkmenistan

Tunisia

Tonga

Turkey

Trinidad & Tobago

Tuvalu

Tanzania

Ukraine

Uganda

U.S. Outlying Islands

United States

Uruguay

Uzbekistan

Vatican City

St. Vincent & Grenadines

Venezuela

British Virgin Islands

U.S. Virgin Islands

Vietnam

Vanuatu

Wallis & Futuna

Samoa

Yemen

Mayotte

South Africa

Zambia

Zimbabwe